Real-time continuous analysis in production of Bauxites & Alumina

Many alumina refineries experience efficiency losses due to the variations in mineralogy and the presence of impurities such as silica, iron oxides and titania in bauxite (the main raw material used in the alumina industry), not only influence its processing efficiency, but can also increase production costs and create quality deficits in the final product. With real-time data received from MAYA OnLine analyzers, it is possible to manage variations in bauxite, reject unacceptable material, blend different grades of bauxites, make real-time adjustments to the addition of lime, sodium hydroxide and other process raw materials and reagents, and to provide improved measure of product quality control. Growth in the global alumina supply and the tendency to process lower grades of bauxite in future will only intensify the demand for reliable tools for real-time measurements. These measurements can provide the data required to manage impurities, and to make prompt corrections to process parameters without the potential delays of up to several hours for sampling and laboratory based results.

Examples of installation

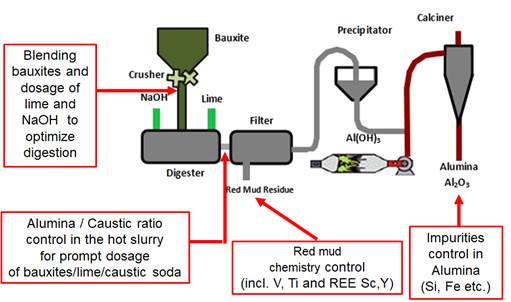

• Control variations in quality of crushed bauxites to reject off-grade material and optimize blending before being mixed with a caustic soda solution

• Accurate dosage of lime, caustic soda (NaOH) to optimize digestion and reduce operating costs

• Control of Alumina/Caustic ratio in the hot slurry to the specified target

• Red mud chemistry control

• Quality control of alumina to avoid negative influence on aluminum metal products

Your benefits withMAYA Online analyzers

• Improved consistency of bauxite quality for alumina refineries

• Optimized digester performance due to timely changes to the Bayer process chemistry

• Increased refinery output

• Reduced operating costs by savings in consumption of energy, dissolving agents (caustic soda), lime

• Reduced variations in alumina quality