Laser (LIBS) cement online analyzer provides accurate and reliable chemical composition data of crushed limestone (source of calcite), clay, mudstone or shale (main source of silica and alumina), iron ore or metallurgical slag (source of iron) on the belt. It lets the operators manage their quarries more efficient and form consistent quality stockpiles. Low-grade materials can be incorporated in the stock formation extending life type of the quarry.

Quick real-time analysis of raw mix, meal, clinker or cement let cement manufacturers automatically adjust the dosage and mixing of raw materials. The stable targeted material chemistry can be maintained with a low standard deviation of Lime Saturation Factor (LSF), Silica (SR), Alumina (AR) Ratios ensuring good quality cement is made. The cement cross belt analyzer can be installed at various points of the production process depending on the application.

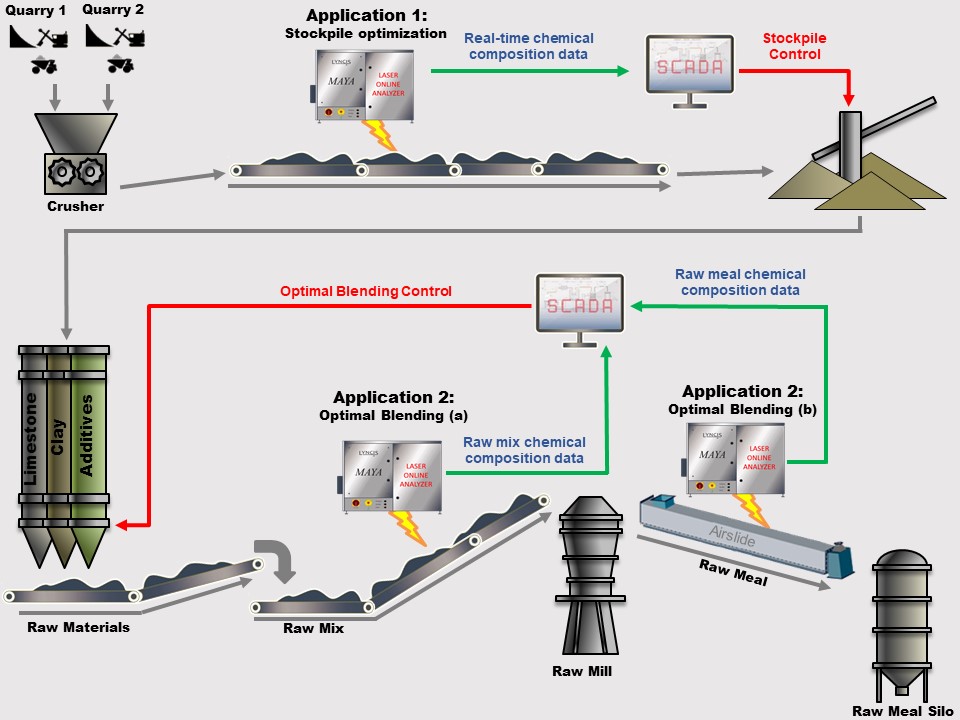

Application 1Stockpile Formation

The analyzer installed after the crusher to analyze incoming raw material from the quarries. The control signal controls stockpile formation and keeps the piles at the desired quality.

Application 2Optimal Blending of Raw Meal

To guarantee the desired quality of raw meal online analyzer can be installed either on a raw mix conveyor belt before the raw mill (a) or on the airslide (b) after the mill. Real-time chemical composition data is used to adjust weight feeders delivering required mix blending.

Application 3Quality control of clinker or cement

The cement crossbelt analyzer can be installed after the kiln or finishing mill to analyze clinker or cement quality. Dosage of gypsum, flyash and other additives can be controlled to achieve desired final product quality.

Advantages of Cement Online Analyser

• High accuracy and stable analysis of Si, Ca, Mg, Na, K, Fe, Al and other required elements. Parameters such as moisture, Lime Saturation Factor (LSF), Silica (SR), Alumina (AR) Ratios can be monitored.

• Environmentally and personnel safe technology

No gamma-ray, neutron or x-ray radiation. No governmental permissions and licenses are needed for operating and transporting the equipment making it simpler and cheaper to manage the production.

No gamma-ray, neutron or x-ray radiation. No governmental permissions and licenses are needed for operating and transporting the equipment making it simpler and cheaper to manage the production.

• Low cost of ownership and maintenance with remote support

• Flexible installation option on a conveyor belt or airside with fully automatic 24/7 operation and SCADA integration

Benefits

• Improved and stable high quality of clinker and cement

• Decrease standard deviation of LSF, SR, AR

• Reduced frequency and cost in lab testing and sample preparation

• Reduced fuel and energy costs

• Kiln stability