Ore Grade Sorting and Stockpile Formation

Understanding the chemical composition of materials for effective ore grade sorting is a decisive factor in achieving higher production output with reduced operational cost. This is especially true in the mining industry, where companies are struggling to stay competitive with volatile commodity prices, declining ore grades and increasing variation in chemical and mineralogical composition in raw materials.

MAYA online elemental analyzer offers radiation free chemical composition analysis of material streams with no sampling and sample preparation.

Continuous data provided by the chemical analyzer is used to optimize ore grade sorting and stockpile formation and helps the miners to extract maximum value from existing ore deposits. With the solution mining and ore processing companies can benefit from:

- Increased recovery of valuable minerals

- Higher-grade product

- Extended lifetime of the mine

- Elimination of time-consuming process of sampling and sample preparation

- Reduced energy and water consumption

Examples of Applications

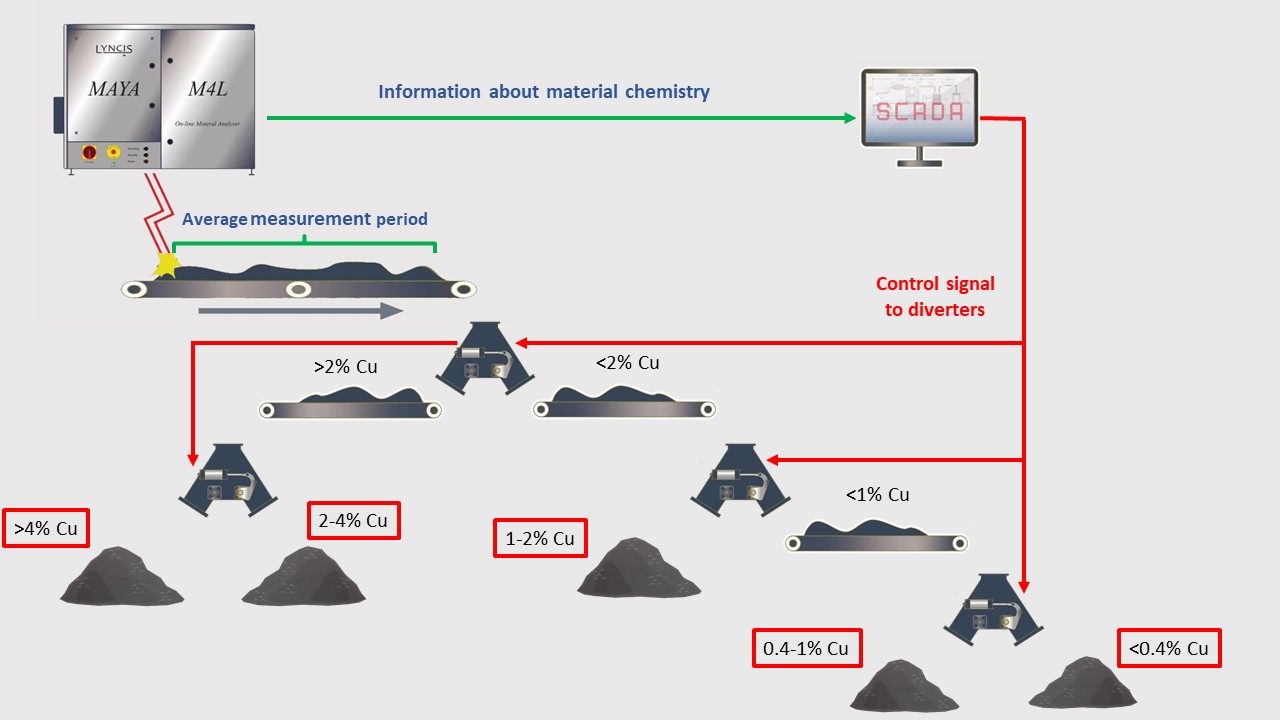

Ore Grade Sorting

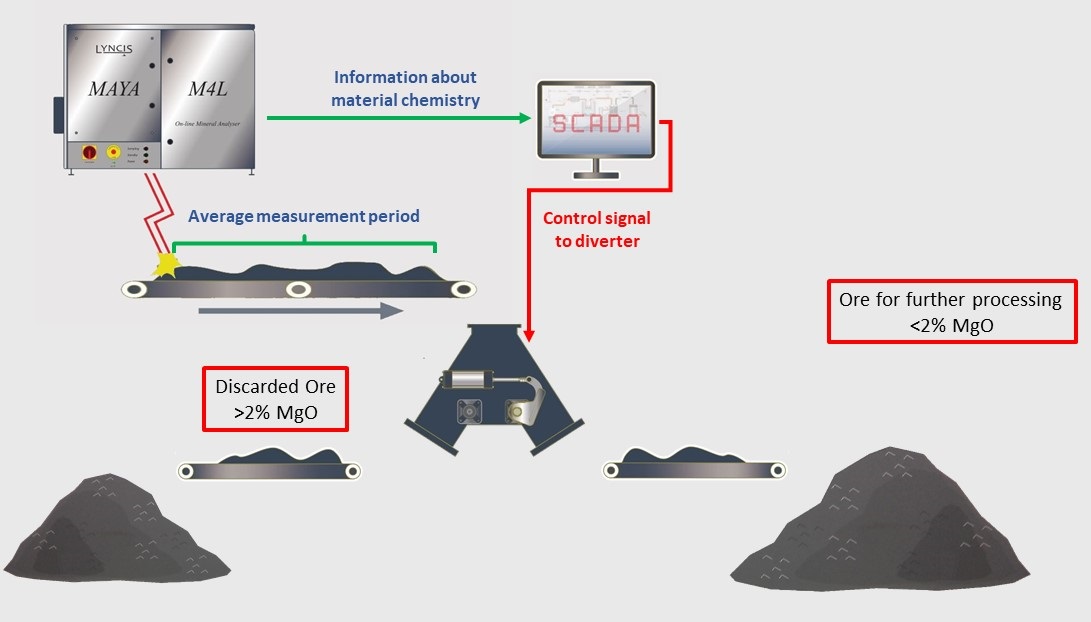

Based on ore quality variation pattern on moving conveyor belt single batch sampling time is selected. The time can vary depending on the rock type, size and conveyor belt length, and usually is between 1 – 10 min.

The elemental analyzer continuously measures copper content in the crushed ore during the sampling period, then the average batch grade is calculated. Depending on the result multiple diverter system is used to divert the measured ore to corresponding stockpile.

In the example above system with one laser elemental analyzer and four diverters controlled by SCADA system is used to sort copper ore into 5 different grade piles.