Introduction

How you can maximize the calibration accuracy of an online analyzer? What parameters influence it and what do you have to pay attention to? Can the accuracy be increased further after commissioning? These are the questions that every user of an online analyzer has and we are going to discuss them in this post. The accuracy of online analyzers can reach 10% of the calibration interval and even higher in some cases. This means if your calibration interval is 5% for a specific element or parameter you can expect the accuracy of 0.5% or higher. In the laboratory, you can expect slightly higher accuracy as analyses are performed in a controlled environment on stationary samples. But please keep in mind that online analyzers operate in industrial environments in the presence of dust, heat, cold, moisture, and vibrations and analyze moving materials. Despite that, the results of online analyzers are close to the laboratory and most importantly the results are provided in real time which allows immediate adjustment of process parameters.

1. Supervise Sample Collection and Preparation

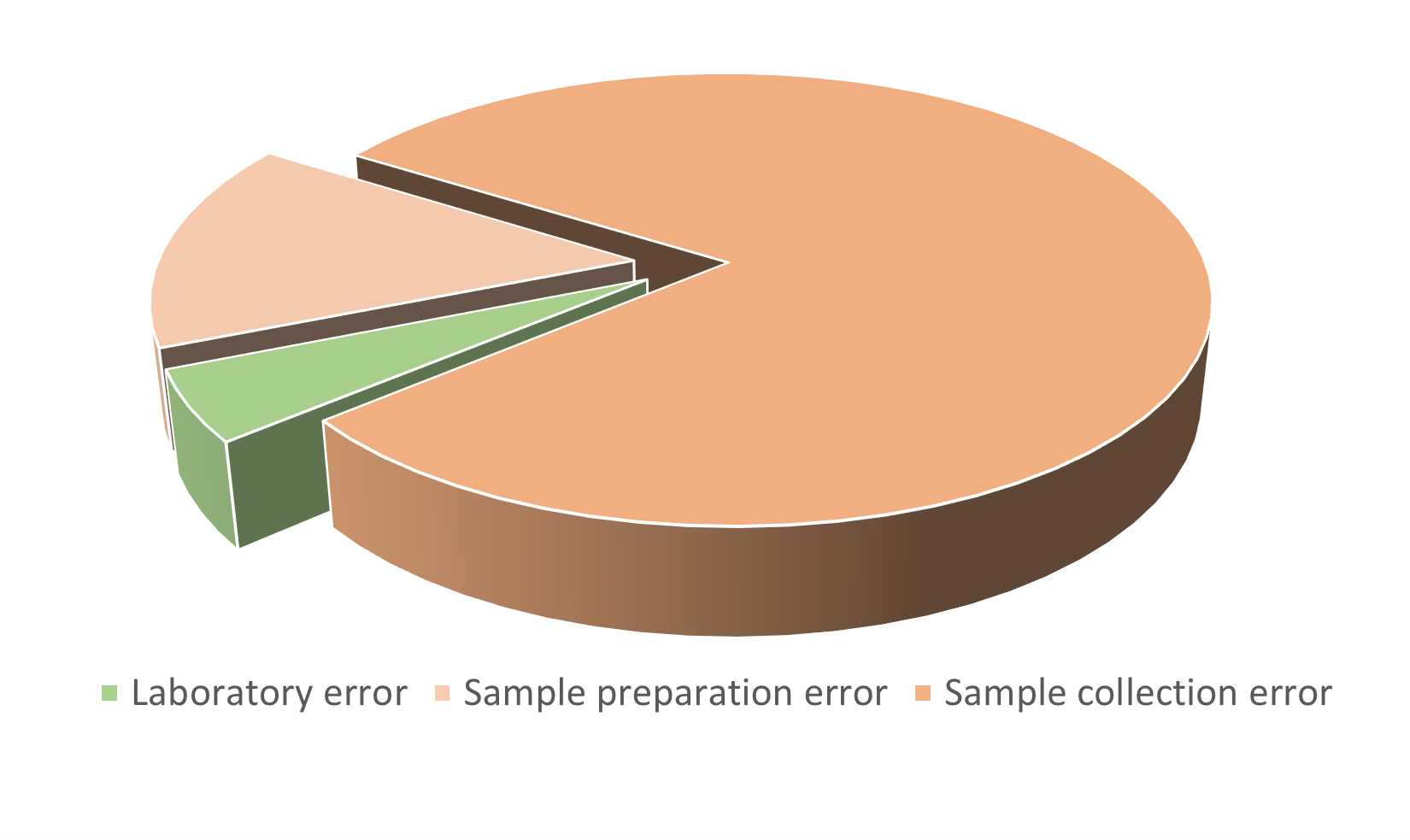

The accuracy of laboratory analysis is typically high. However, laboratory analysis influences only ~5% of the accuracy. ~80% comes from sample collection and another ~15% from sample preparation. Therefore you have to pay attention and supervise closely your sample collection and preparation processes. Let’s be honest, an unattended staff will try to cut corners, that’s human nature!

2. Cover Full Calibration Interval

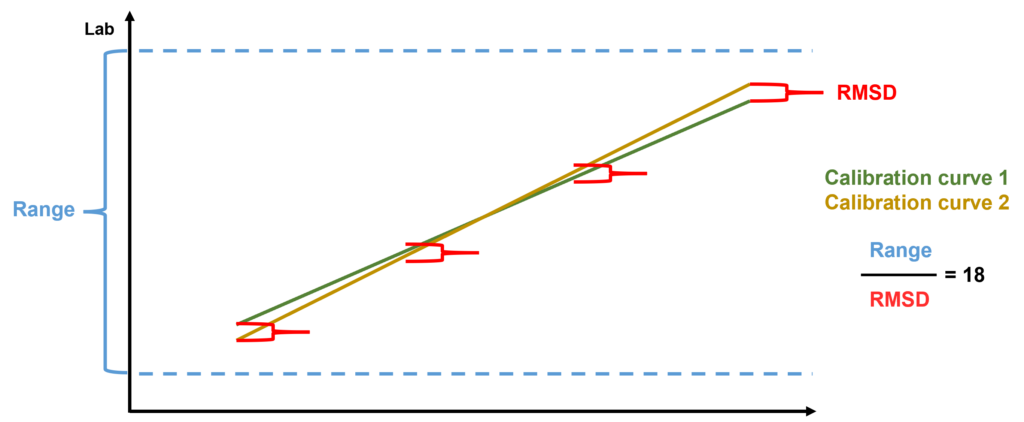

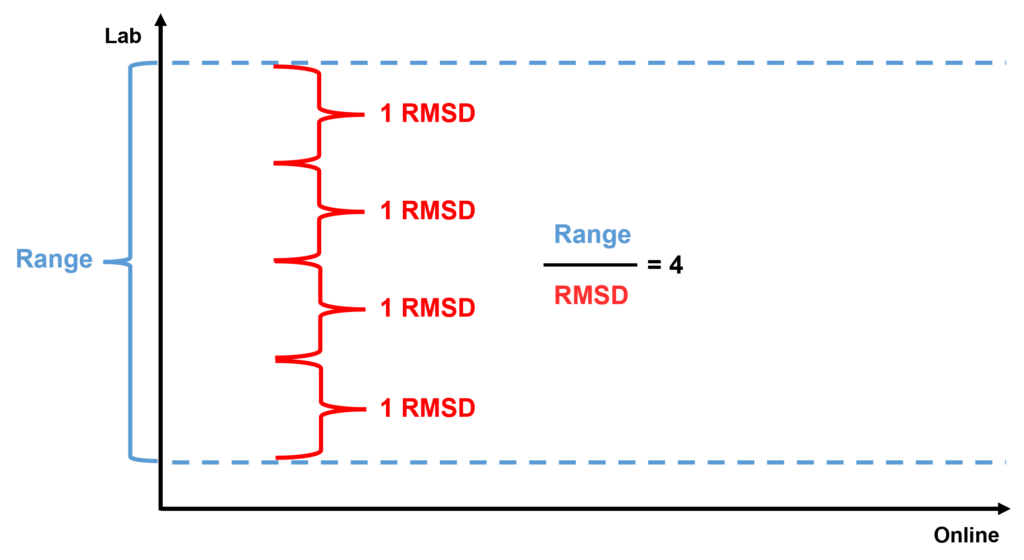

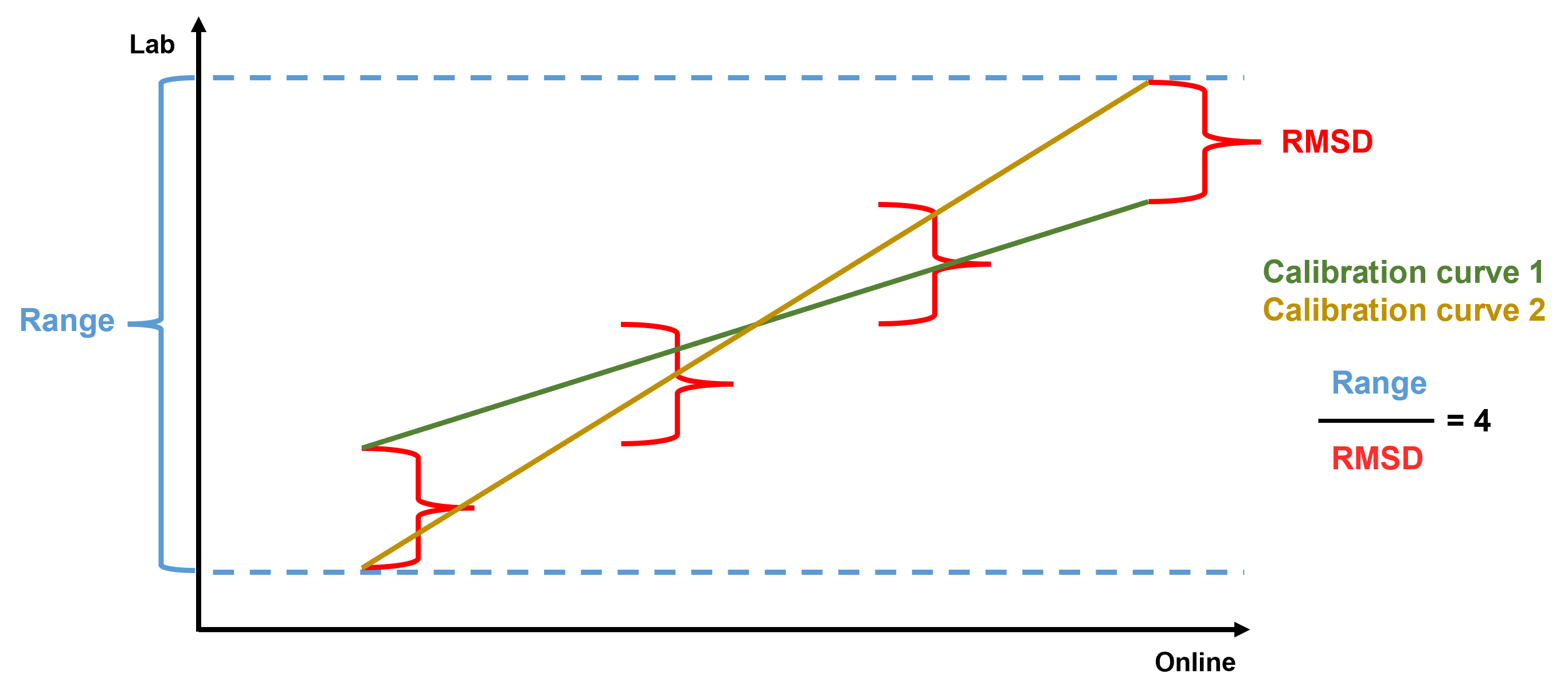

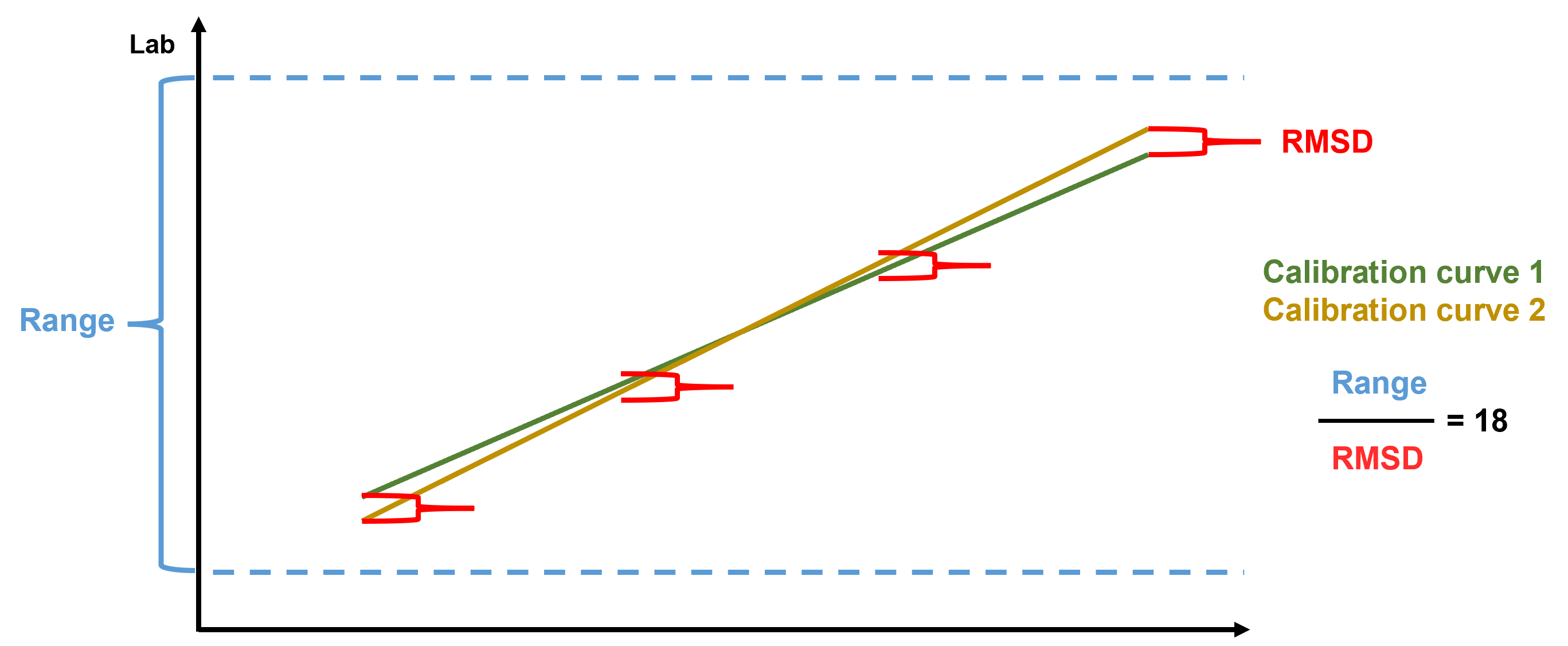

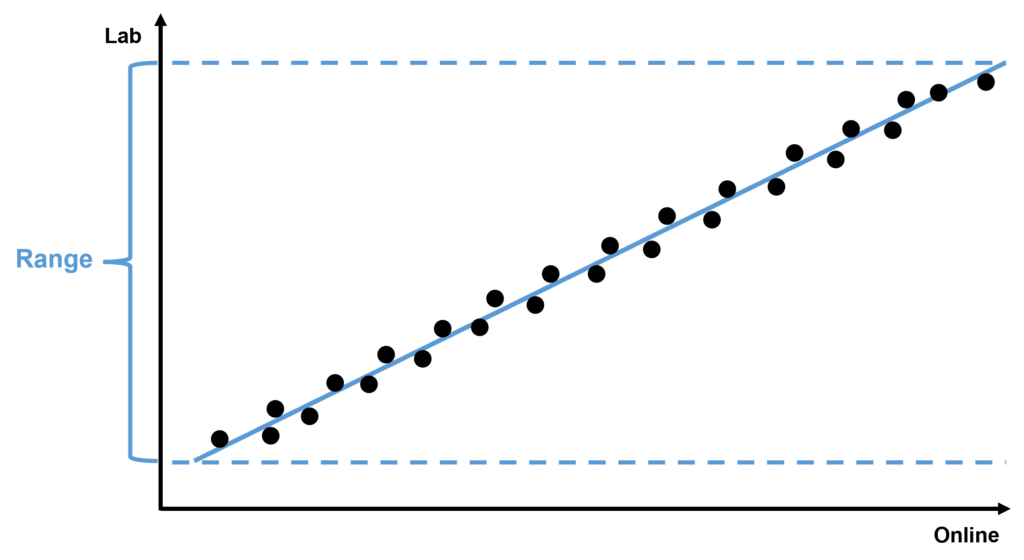

A ratio of calibration interval with laboratory RMSD is a sound indicator of calibration quality. The higher value of the ratio the higher the calibration accuracy. Often the samples collected from the process tend to have low concentration variation not covering the full concentration range. During the calibration stage, you should change process parameters on purpose to cover the full concentration range.

3. Decrease RMSD

Another part of the equation is RMSD. Let’s have a look at two cases with ratio values of 4 and 18. As you can see with the increase of “Range / RMSD” ratio value the border cases of calibration (Calibration curve 1 and Calibration curve 2) get close to each other and close to the actual calibration curve.

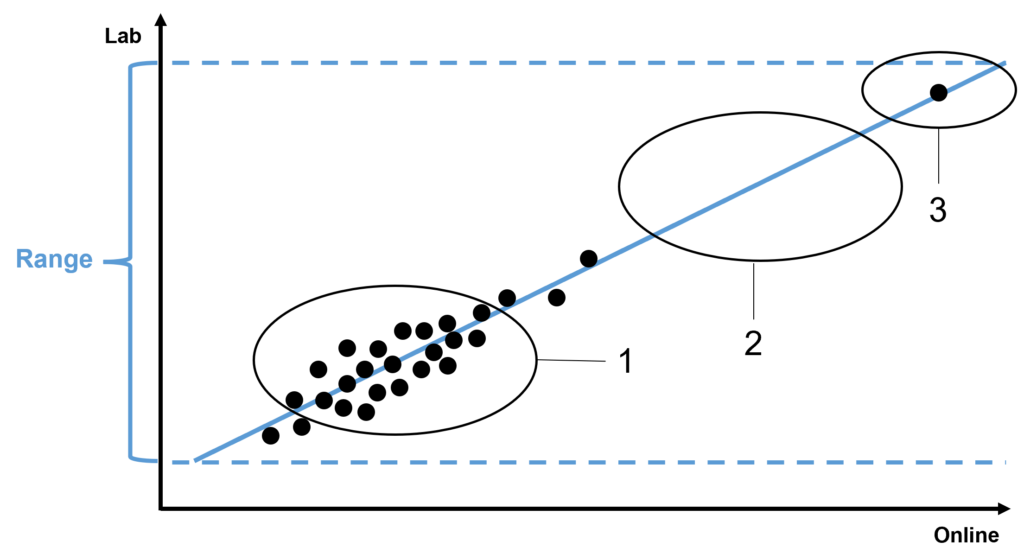

4. Ensure Uniform Distribution of Calibration Points

You have probably seen a similar view in the picture below many times. That’s a typical situation when calibration points tend to crowd at a certain concentration range leaving just a few points at another end. That single point at a high concentration range is going to make a huge impact on the calibration curve, but the problem is that a single point is not enough. In addition, many points in a narrow calibration range will add a lot of weight to the calibration algorithm potentially steering it in the wrong direction. You have to avoid such situations and try to cover a full concentration range with a uniform distribution.

5. Calibrate on Process Material

For accurate calibration, you should collect the same type of material from the process that you will be analyzing. Only this will allow taking into consideration all the factors related to the particular sample like matrix effects, etc. In addition, it is important to collect samples close to the installation location of the online analyzer, because the material may change down the process i.e. lose or acquire moisture.

6. Always Closely Follow Suppliers Guidelines

You can find several universal guidelines on sample collection, preparation and calibration of online analyzers, i.e.:

- ISO 11648-1 – Statistical aspects of sampling from bulk materials

- ISO 3085 – Iron ores — Experimental methods for checking the precision of sampling, sample preparation and measurement

- ISO 13909-7 – Hard coal and coke — Mechanical sampling

- ISO 15239 – Solid mineral fuels — Evaluation of the measurement performance of on-line analysers

- ASTM D 6543 – Standard Guide to the Evaluation of Measurements Made by On-Line Coal Analyzers

However, you should always follow the guidelines provided by the supplier, as there might be factors specific to different analyzer technology. For example, the number of samples required for calibration may be different for different analyzer technologies, it may be related to the number of interacting elements in the sample, etc. In addition, each supplier has acquired a lot of experience from the field specific to its technology which may not be applicable for another technology.

7. Start by Choosing Optimal Location

Finally – you should think of the accuracy right from the start of the project when choosing an installation location for an online analyzer. Often locations allowing minimizing of systematic segregation and thus maximizing accuracy are located close to discharge chutes and can be identified by studying process diagrams. For a discussion on optimal installation location please check our post: https://www.lyncis.lt/conveyor-or-airslide/

Closing

Let us summarize – to get an accurate calibration of the online analyzer you should cover the whole concentration range of interest with a uniform distribution of calibration points and increase the ratio of concentration range with laboratory RMSD. The accuracy of the online analyzer can be increased even after the completion of commissioning. Did you ever think that an online analyzer could be useful even without completed commissioning and calibration? It does – it allows you to receive concentration trends in real-time and although they are not completely accurate at that time, they provide valuable insights about possible problems and allow taking immediate action!

About the Author

Mindaugas Dailide is an experienced sales professional with a technical background focused on delivering optimal solutions to customers.