With the volatile commodity prices, increasing energy cost and declining ore grades mineral processing companies are more than ever forced to look for solutions for higher efficiency and sustainability in the production process.

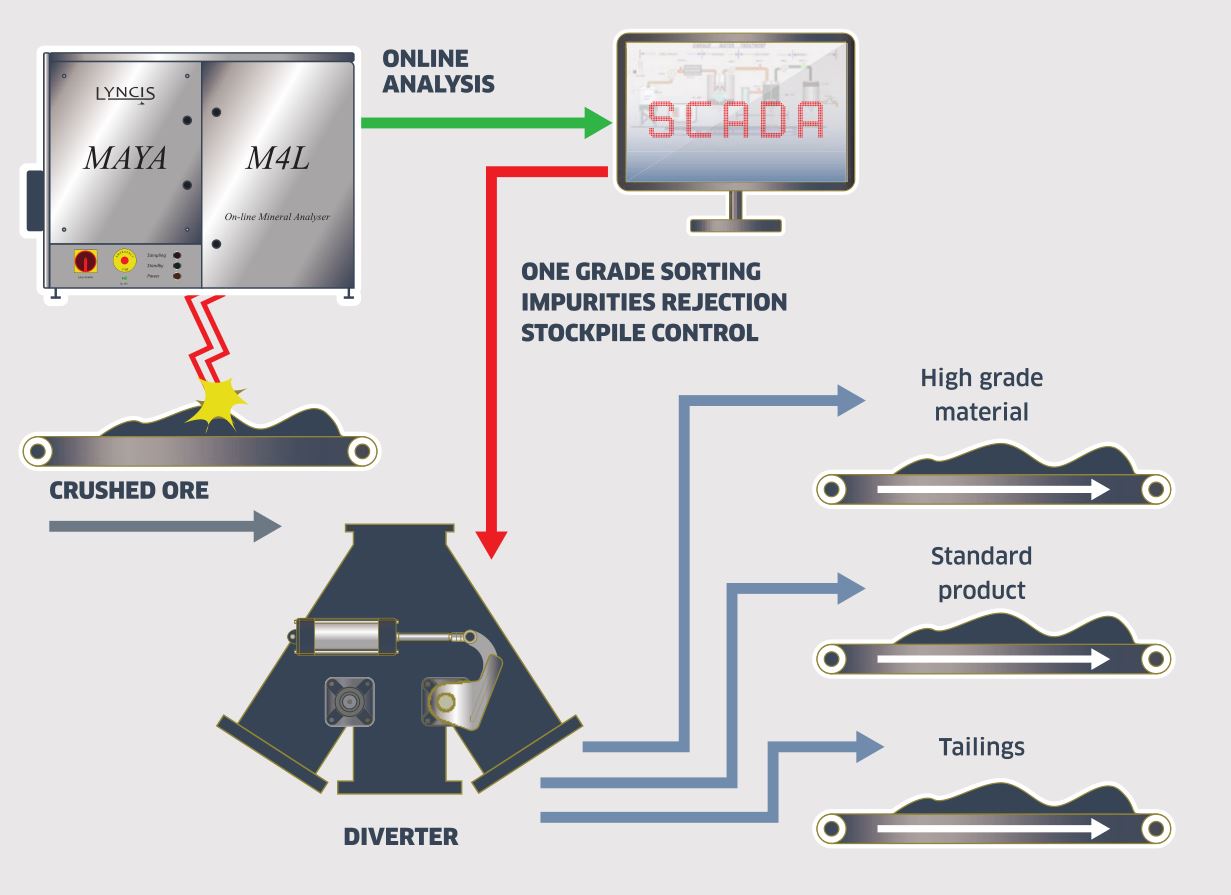

Modern sensor technology and deep knowledge of raw material chemistry help the producers to maximize the recovery of minerals and extract additional value from lowest grade ore, which wasn’t possible before.

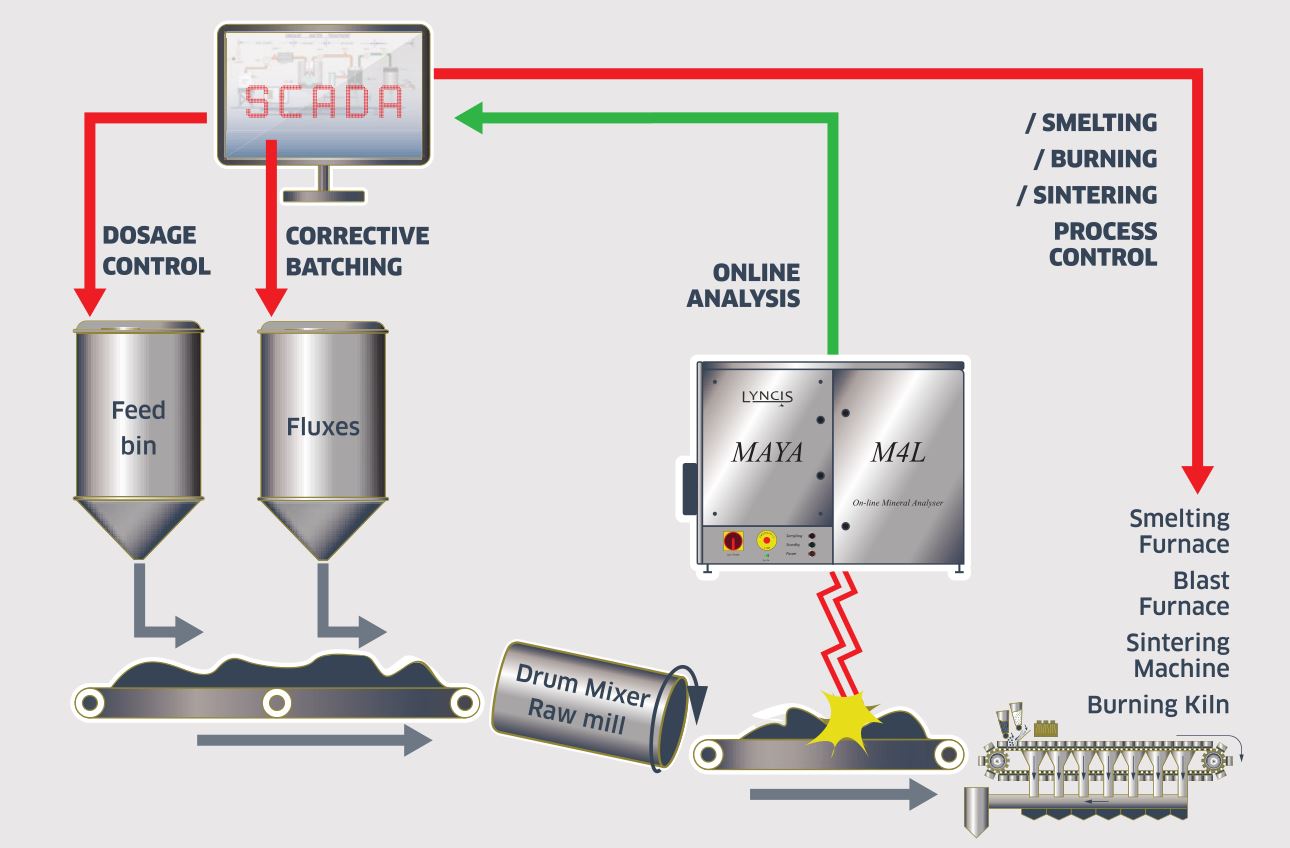

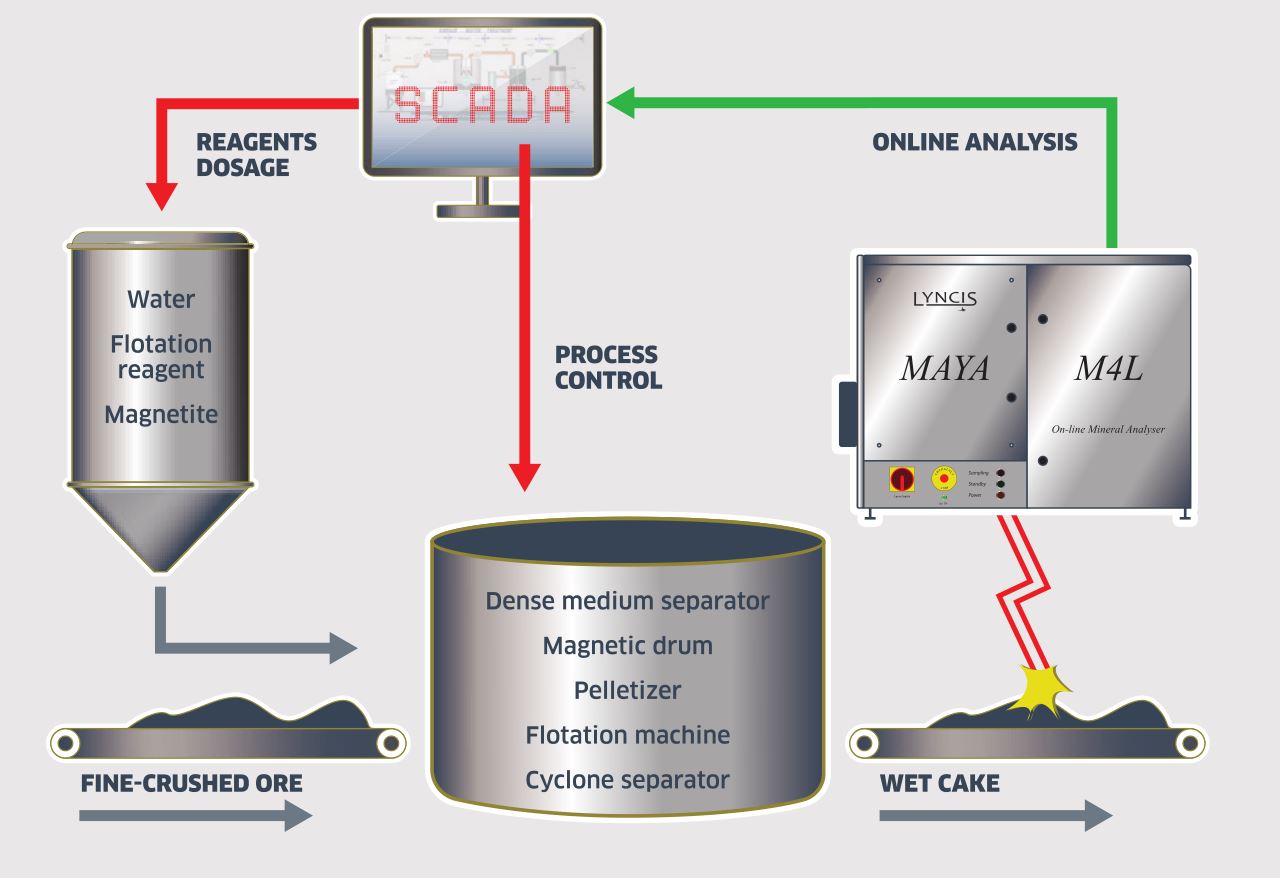

With advanced process control based on real-time chemical composition data, the manufacturers are not just able to increase valuable minerals yield but also minimize operational cost. The improved production process can deliver reduced energy, water, and flotation reagents consumption. Production downtime can be minimized by promptly addressing product quality discrepancies.

Lyncis Radiation-Free Online Elemental Analyzers bring together experience in mining and mineral processing applications and advance chemical analytics to enable timely and accurate decision making at every stage of the process.